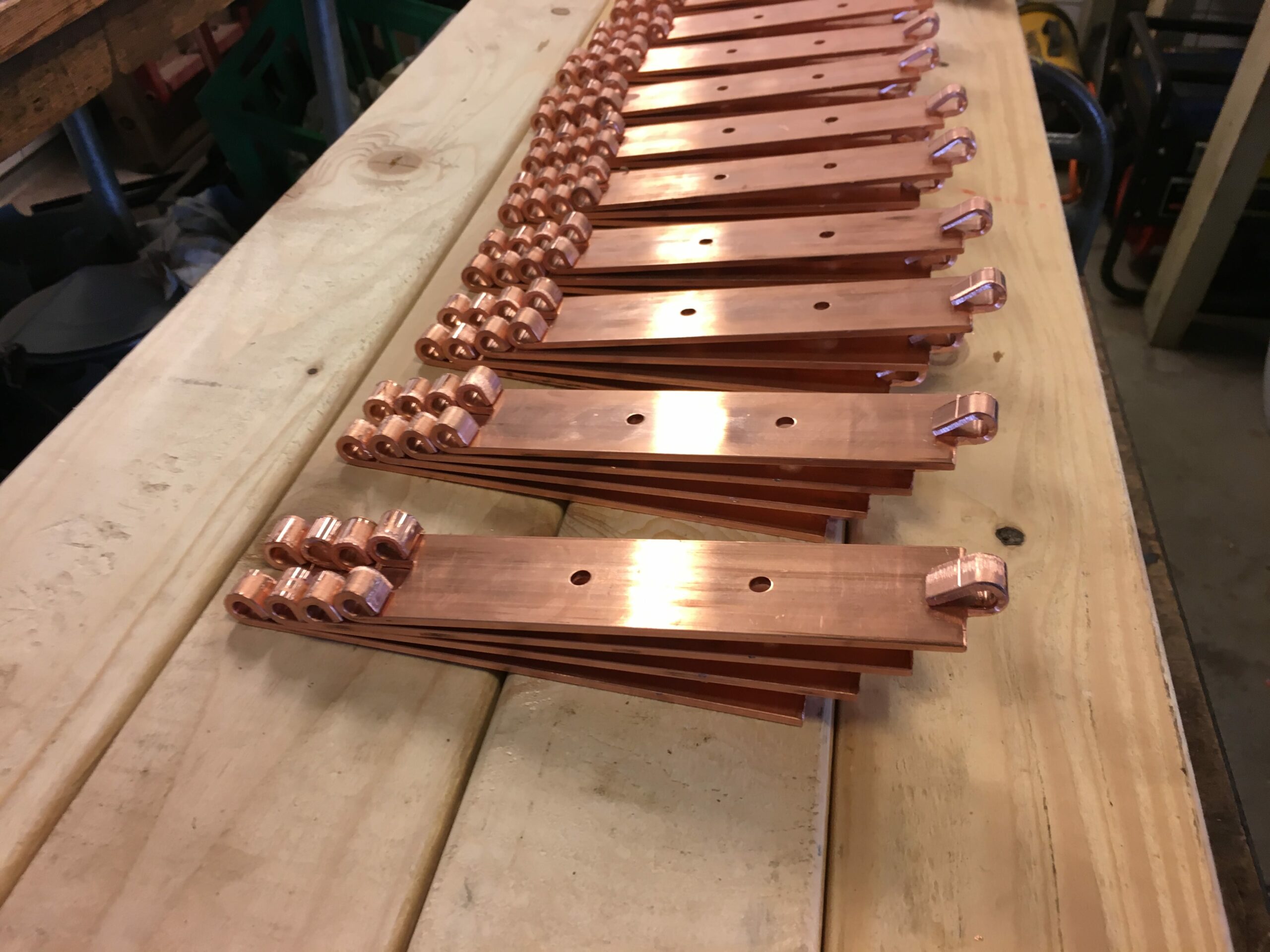

finished result Finished work – a task that we are very proud of. See the process in the pictures below. We have in-depth material if you are interested in more information about this. The old roof This was the old copper roof we came to. It was without ventilation of any kind, at the same time as the roof had released the wooden base. There was a big task ahead of us. At the top are our handmade round windows At the bottom are our very own hinge pins. When you have to make the tower on the arch, it is important to know your techniques. Here we proved that the large rounding up, which also curves in two directions, can be done without bumps. It is for information not printed on a machine, it is pure needlework throughout. It is usually not difficult to make one profile in copper, it is much harder and must make a minimum of 30 pieces which must then be completely the same and fit together. The actual copper shoe trend perform to begin with. Here the shoe trend is over. Note that we have performed the actual hiking with round water repellent. Here is a small delicious piece of craftsmanship. Then we are in the process of mounting the copper roof itself. In the construction itself, we were very aware that a lot of ventilation was needed. This meant that we used an old design on the air caps, which was previously approved by the then Cultural Heritage Agency now SLKS. Upon 1 year of review with the builder and architect, we were able to ascertain that the air under the church roof was unusually good. Here the roofs are assembled at the top The actual closing of the roofs is not what is called a tower closing seam, but the degree of difficulty is definitely present – again there is a focus on folding irons, hammers and tools not making unnecessary dents in the roof. The closed copper roof with lightning conductor Here you can see the closure up close. All in all, a task we are all very proud of. Workshop work for master, when it is very busy – this is 1 week production approx. 30 hours It was very important that the “master” did not get sweat on his forehead and that the journeymen could approve the result 🙂

Skt. Katharina Kirke – Store Heddinge

Client

ward council

Architect

Henning Johansen

Conducted

2015